Copyright © 2025 Chuangming Coupling (Jiangsu) Co.,Ltd.

GC Drum gear coupling(Q/YG 13010X-2018)

The GC type drum gear coupling is a robust and efficient mechanical coupling device designed to transmit torque between two shafts while accommodating misalignment and shaft movement. Known for its reliability and durability, the GC coupling is widely used in various industrial applications where precise torque transmission is crucial.

Key features of the GC type drum gear coupling include:

-

High Torque Capacity: The coupling is engineered to handle high torque loads, making it suitable for heavy-duty applications such as mining, steel mills, and power generation.

-

Flexible Design: Its flexible design allows for angular, parallel, and axial misalignment between shafts, reducing stress on connected equipment and minimizing the risk of premature failure.

-

Simple Installation: With its straightforward installation process, the GC coupling facilitates quick and easy setup, minimizing downtime during machinery maintenance or replacement.

-

Durable Construction: Constructed from high-quality materials such as steel or alloy, the coupling is built to withstand harsh operating conditions, including extreme temperatures, corrosive environments, and heavy vibrations.

-

Low Maintenance: The robust design of the GC coupling requires minimal maintenance, resulting in cost savings and increased uptime for industrial operations.

-

Interchangeability: GC couplings are often designed to be interchangeable with other coupling brands, providing flexibility for machinery upgrades or replacements without significant modifications.

-

Versatile Applications: From conveyors and pumps to compressors and turbines, the GC type drum gear coupling finds applications across a wide range of industries, contributing to efficient power transmission and machinery performance.

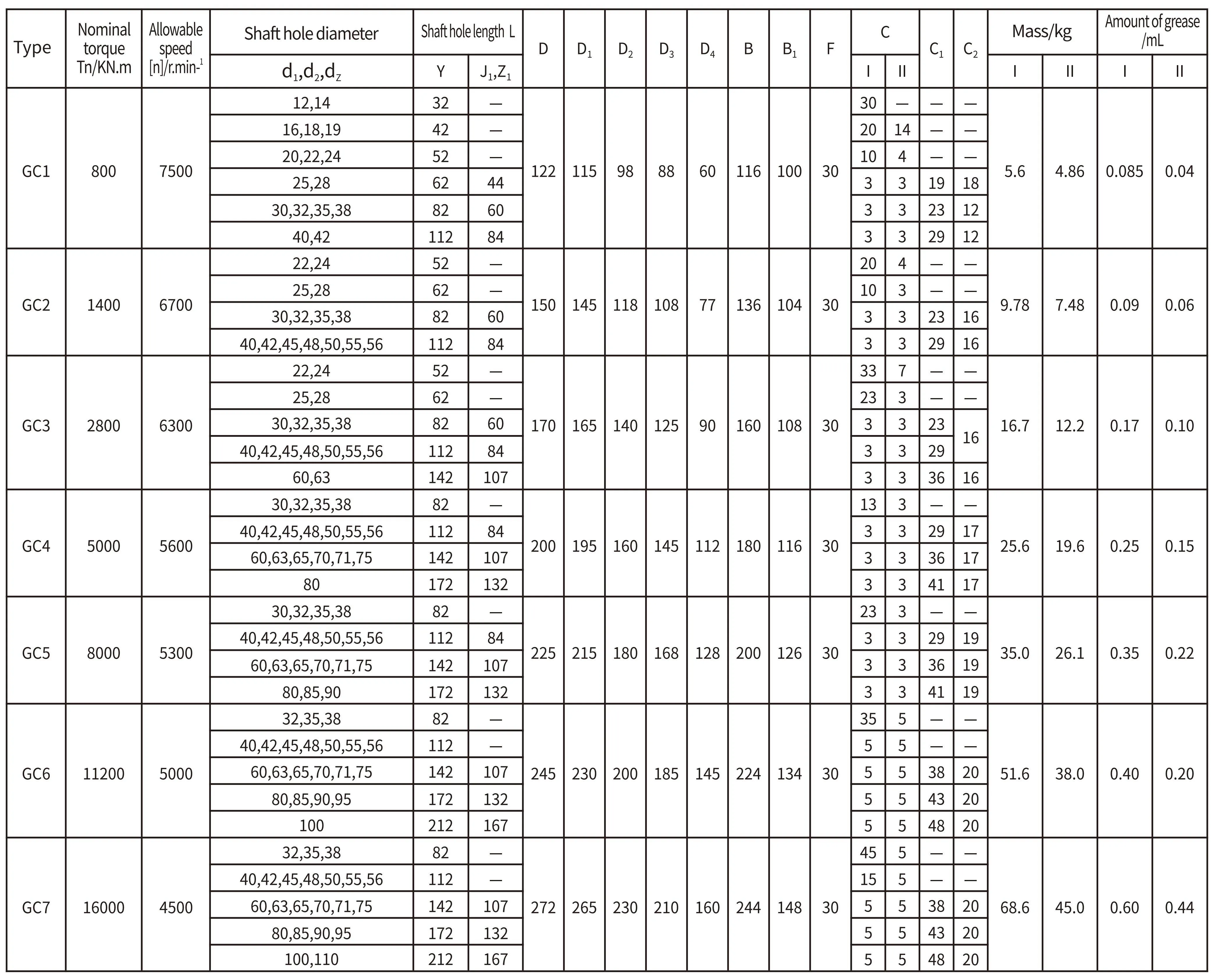

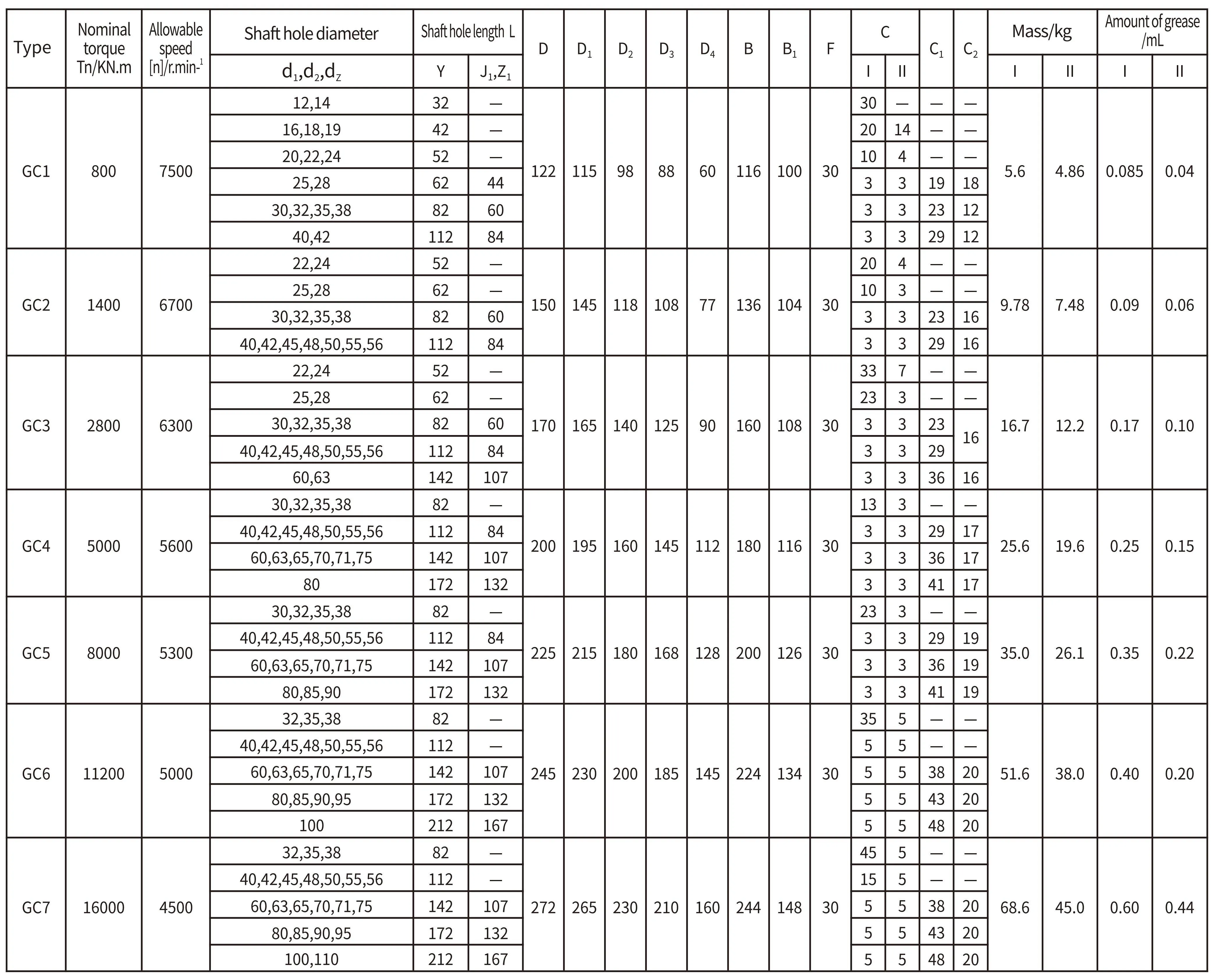

Basic parameters and main dimensions of GC-type drum gear coupling

In summary, the GC type drum gear coupling is a reliable and versatile coupling solution known for its high torque capacity, flexibility, durability, and ease of installation. Its ability to accommodate misalignment and withstand harsh operating conditions makes it a preferred choice for demanding industrial environments.

The GC type drum gear coupling is a robust and efficient mechanical coupling device designed to transmit torque between two shafts while accommodating misalignment and shaft movement. Known for its reliability and durability, the GC coupling is widely used in various industrial applications where precise torque transmission is crucial.

Key features of the GC type drum gear coupling include:

-

High Torque Capacity: The coupling is engineered to handle high torque loads, making it suitable for heavy-duty applications such as mining, steel mills, and power generation.

-

Flexible Design: Its flexible design allows for angular, parallel, and axial misalignment between shafts, reducing stress on connected equipment and minimizing the risk of premature failure.

-

Simple Installation: With its straightforward installation process, the GC coupling facilitates quick and easy setup, minimizing downtime during machinery maintenance or replacement.

-

Durable Construction: Constructed from high-quality materials such as steel or alloy, the coupling is built to withstand harsh operating conditions, including extreme temperatures, corrosive environments, and heavy vibrations.

-

Low Maintenance: The robust design of the GC coupling requires minimal maintenance, resulting in cost savings and increased uptime for industrial operations.

-

Interchangeability: GC couplings are often designed to be interchangeable with other coupling brands, providing flexibility for machinery upgrades or replacements without significant modifications.

-

Versatile Applications: From conveyors and pumps to compressors and turbines, the GC type drum gear coupling finds applications across a wide range of industries, contributing to efficient power transmission and machinery performance.

Basic parameters and main dimensions of GC-type drum gear coupling

In summary, the GC type drum gear coupling is a reliable and versatile coupling solution known for its high torque capacity, flexibility, durability, and ease of installation. Its ability to accommodate misalignment and withstand harsh operating conditions makes it a preferred choice for demanding industrial environments.