Copyright © 2025 Chuangming Coupling (Jiangsu) Co.,Ltd.

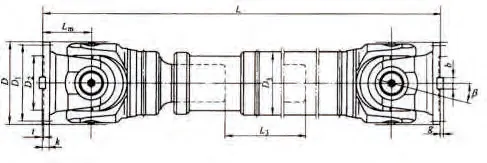

SWC-CH type long expansion welding universal coupling

Introduction: The SWC-CH Type Long Expansion Welding Universal Coupling embodies a sophisticated engineering solution tailored for applications demanding efficient torque transmission along with the benefits of long expansion capability. Engineered with precision, durability, and ease of installation through welding, this coupling is designed to excel in diverse industrial settings where reliable power transmission and adaptability to axial movement are essential.

Key Features:

-

Long Expansion Design: The SWC-CH coupling is equipped with a long expansion feature, allowing for substantial axial movement. This makes it particularly well-suited for applications where thermal expansion or contraction, as well as significant axial displacements, are considerations.

-

Welding Simplicity: Featuring a welded joint design, the coupling ensures a secure and robust connection between shafts. The welding simplicity enhances ease of installation, contributing to a quick and efficient integration process in various industrial systems.

-

Universal Joint Configuration: With a universal joint design, the SWC-CH coupling excels in compensating for angular misalignments, reducing stress on connected machinery components, and promoting smooth and reliable operation even in applications with dynamic conditions.

-

Durable Construction: Crafted from high-quality materials, the coupling is engineered for durability, providing longevity and reliability in challenging industrial environments.

-

Precision Engineering: The coupling is precision-engineered to optimize torque transmission efficiency, ensuring minimal power loss and reducing wear and tear on connected equipment.

-

Versatility in Applications: The SWC-CH coupling finds applications in various industries, including petrochemical, marine engineering, steel production, and conveyor systems, where its long expansion design and welding simplicity offer adaptability to dynamic operating conditions.

Applications:

The SWC-CH Type Long Expansion Welding Universal Coupling is well-suited for a range of applications, including:

- Petrochemical Industries

- Marine Engineering

- Steel Production

- Conveyor Systems

Conclusion:

The SWC-CH Type Long Expansion Welding Universal Coupling stands as an advanced solution for industrial applications requiring not only efficient torque transmission but also adaptability to long axial movements. Its long expansion design, welding simplicity, and versatility make it an ideal choice for industries prioritizing durability, ease of installation, and reliable performance in power transmission systems subjected to dynamic conditions.

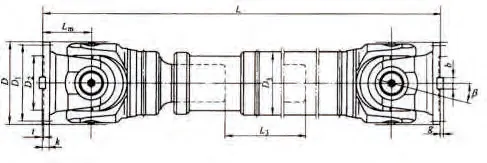

Introduction: The SWC-CH Type Long Expansion Welding Universal Coupling embodies a sophisticated engineering solution tailored for applications demanding efficient torque transmission along with the benefits of long expansion capability. Engineered with precision, durability, and ease of installation through welding, this coupling is designed to excel in diverse industrial settings where reliable power transmission and adaptability to axial movement are essential.

Key Features:

-

Long Expansion Design: The SWC-CH coupling is equipped with a long expansion feature, allowing for substantial axial movement. This makes it particularly well-suited for applications where thermal expansion or contraction, as well as significant axial displacements, are considerations.

-

Welding Simplicity: Featuring a welded joint design, the coupling ensures a secure and robust connection between shafts. The welding simplicity enhances ease of installation, contributing to a quick and efficient integration process in various industrial systems.

-

Universal Joint Configuration: With a universal joint design, the SWC-CH coupling excels in compensating for angular misalignments, reducing stress on connected machinery components, and promoting smooth and reliable operation even in applications with dynamic conditions.

-

Durable Construction: Crafted from high-quality materials, the coupling is engineered for durability, providing longevity and reliability in challenging industrial environments.

-

Precision Engineering: The coupling is precision-engineered to optimize torque transmission efficiency, ensuring minimal power loss and reducing wear and tear on connected equipment.

-

Versatility in Applications: The SWC-CH coupling finds applications in various industries, including petrochemical, marine engineering, steel production, and conveyor systems, where its long expansion design and welding simplicity offer adaptability to dynamic operating conditions.

Applications:

The SWC-CH Type Long Expansion Welding Universal Coupling is well-suited for a range of applications, including:

- Petrochemical Industries

- Marine Engineering

- Steel Production

- Conveyor Systems

Conclusion:

The SWC-CH Type Long Expansion Welding Universal Coupling stands as an advanced solution for industrial applications requiring not only efficient torque transmission but also adaptability to long axial movements. Its long expansion design, welding simplicity, and versatility make it an ideal choice for industries prioritizing durability, ease of installation, and reliable performance in power transmission systems subjected to dynamic conditions.