Copyright © 2025 Chuangming Coupling (Jiangsu) Co.,Ltd.

GCP Drum gear coupling with brake disc(Q/YG 13012X-2018)

The Drum Gear Coupling with Brake Disc represents a sophisticated solution for power transmission systems requiring both reliable coupling and emergency braking capabilities. Combining the robustness of gear couplings with the braking functionality of disc brakes, this hybrid design ensures efficient power transfer while offering enhanced safety features.

|

Typel,type l with brake disc drum gear coupling |

Type lll,typelV with brake disc drum type tooth coupling |

Key Features:

-

Dual Functionality: Integrating a drum gear coupling with a brake disc provides a dual-function system that facilitates both power transmission and emergency braking. This combination optimizes space utilization and simplifies installation in various industrial applications.

-

High Torque Capacity: Drum gear couplings are renowned for their high torque capacity, making them suitable for heavy-duty applications where substantial power transmission is required. The addition of a brake disc further enhances the versatility and performance of the coupling assembly.

-

Precise Control: The inclusion of a brake disc enables precise control over rotational motion, allowing operators to quickly halt machinery in emergency situations or control rotational speed during regular operation. This feature enhances safety and operational efficiency in industrial environments.

-

Durability and Reliability: Both drum gear couplings and brake discs are engineered for durability and reliability in demanding environments. Their robust construction and materials ensure long-term performance and minimal maintenance requirements, contributing to overall system uptime and productivity.

-

Adaptability: Drum gear couplings with brake discs are adaptable to a wide range of applications, including heavy machinery, conveyor systems, cranes, and industrial drives. Their versatility makes them suitable for diverse industrial sectors such as mining, manufacturing, and material handling.

Basic parameters and main dimensions of GCP type drum gear coupling with brake disc

How It Works: The drum gear coupling with brake disc operates by transmitting torque between two shafts while incorporating a braking mechanism for emergency stopping. During regular operation, the gear coupling efficiently transfers rotational motion between the connected shafts, ensuring smooth power transmission. In the event of an emergency or when precise speed control is required, the brake disc is engaged, exerting frictional force to decelerate or stop the rotating components swiftly and safely.

Applications:

-

Industrial Machinery: Used in heavy-duty machinery such as crushers, mixers, and extruders where reliable power transmission and emergency braking are critical.

-

Material Handling Equipment: Employed in conveyors, hoists, and cranes to transmit power and provide emergency braking capabilities for safe and efficient material handling operations.

-

Mining Equipment: Applied in mining conveyors, crushers, and draglines to ensure reliable power transmission and emergency stopping functionality, enhancing safety in challenging mining environments.

-

Marine Propulsion Systems: Utilized in marine propulsion systems to transmit power from engines to propeller shafts while incorporating emergency braking features for maneuverability and safety.

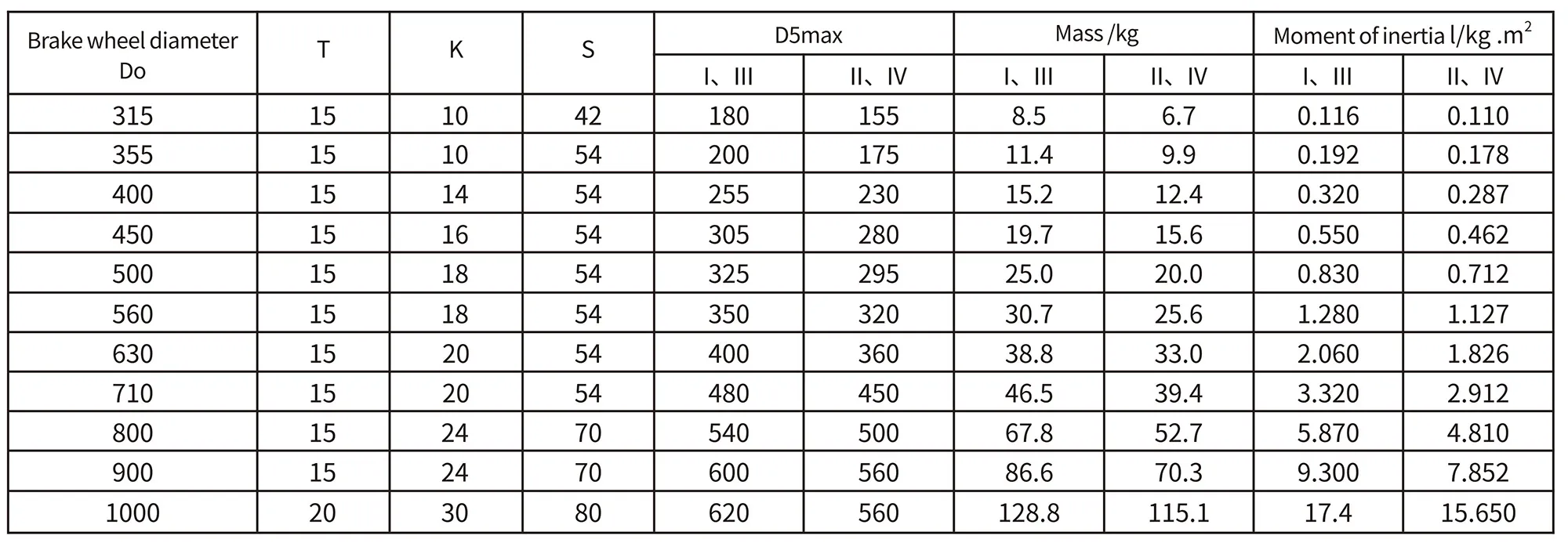

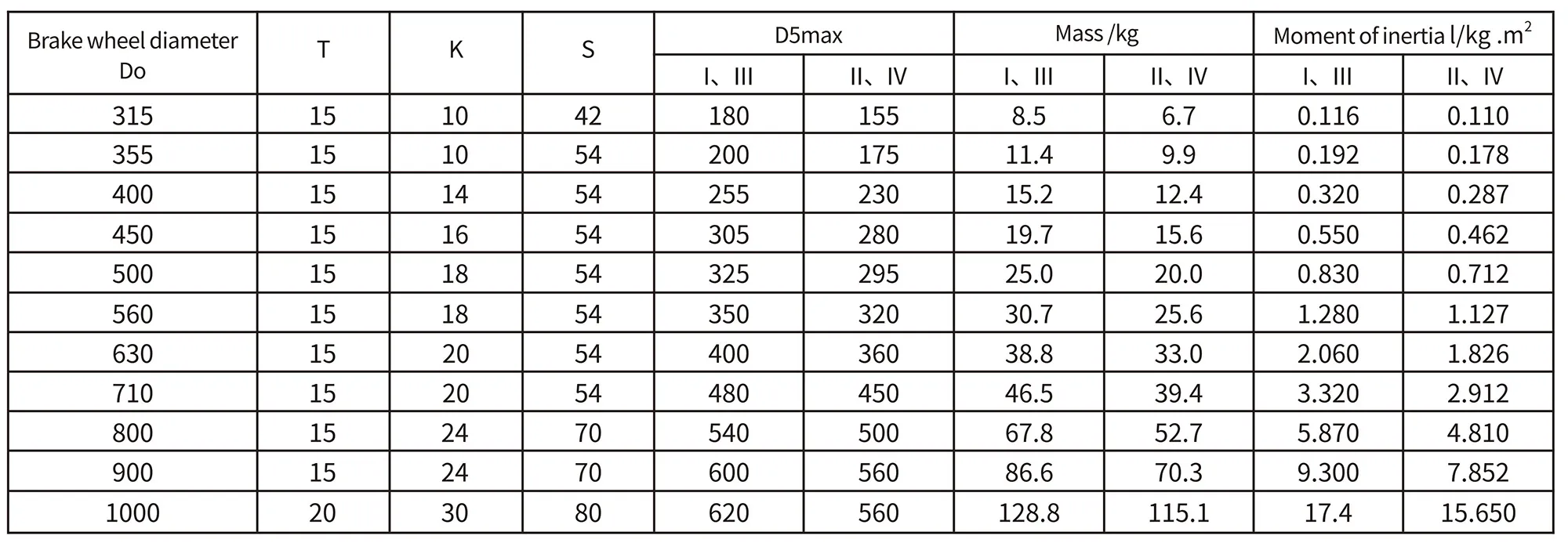

Brake disc main size,mass,moment of inertia

Note:1.The mass and moment of inertia are the approximate values calculated according to theY-shaped shaft hole diameter of the largest shaft hole,and the brake wheel is not calculated.The brake wheel mass is shown in the table of"main size,mass and moment of inertia of the brake wheel".

2.Maximum shaft hole diameter of cone shaft to 220mm.

3.The values ofC,Gand C2 of different brake wheel diameters are the values in the table plus K/2,and the K values are shown in the table of"main size,mass and moment of inertla of brake discn

4.N=5-K/2;The values ofS and Kareshownin Table4-21.The value Nin the table is thecalculated value when the diameter ofthe brake disc is the largest.

Future Outlook: The integration of drum gear couplings with brake discs represents a significant advancement in power transmission technology, offering enhanced safety and operational efficiency across various industrial sectors. As industries continue to prioritize safety and reliability, the demand for innovative coupling solutions capable of combining power transmission and braking functionalities is expected to grow. Further research and development efforts may focus on optimizing the design, materials, and performance characteristics of drum gear couplings with brake discs to meet evolving industrial requirements and regulatory standards.

The Drum Gear Coupling with Brake Disc represents a sophisticated solution for power transmission systems requiring both reliable coupling and emergency braking capabilities. Combining the robustness of gear couplings with the braking functionality of disc brakes, this hybrid design ensures efficient power transfer while offering enhanced safety features.

|

Typel,type l with brake disc drum gear coupling |

Type lll,typelV with brake disc drum type tooth coupling |

Key Features:

-

Dual Functionality: Integrating a drum gear coupling with a brake disc provides a dual-function system that facilitates both power transmission and emergency braking. This combination optimizes space utilization and simplifies installation in various industrial applications.

-

High Torque Capacity: Drum gear couplings are renowned for their high torque capacity, making them suitable for heavy-duty applications where substantial power transmission is required. The addition of a brake disc further enhances the versatility and performance of the coupling assembly.

-

Precise Control: The inclusion of a brake disc enables precise control over rotational motion, allowing operators to quickly halt machinery in emergency situations or control rotational speed during regular operation. This feature enhances safety and operational efficiency in industrial environments.

-

Durability and Reliability: Both drum gear couplings and brake discs are engineered for durability and reliability in demanding environments. Their robust construction and materials ensure long-term performance and minimal maintenance requirements, contributing to overall system uptime and productivity.

-

Adaptability: Drum gear couplings with brake discs are adaptable to a wide range of applications, including heavy machinery, conveyor systems, cranes, and industrial drives. Their versatility makes them suitable for diverse industrial sectors such as mining, manufacturing, and material handling.

Basic parameters and main dimensions of GCP type drum gear coupling with brake disc

How It Works: The drum gear coupling with brake disc operates by transmitting torque between two shafts while incorporating a braking mechanism for emergency stopping. During regular operation, the gear coupling efficiently transfers rotational motion between the connected shafts, ensuring smooth power transmission. In the event of an emergency or when precise speed control is required, the brake disc is engaged, exerting frictional force to decelerate or stop the rotating components swiftly and safely.

Applications:

-

Industrial Machinery: Used in heavy-duty machinery such as crushers, mixers, and extruders where reliable power transmission and emergency braking are critical.

-

Material Handling Equipment: Employed in conveyors, hoists, and cranes to transmit power and provide emergency braking capabilities for safe and efficient material handling operations.

-

Mining Equipment: Applied in mining conveyors, crushers, and draglines to ensure reliable power transmission and emergency stopping functionality, enhancing safety in challenging mining environments.

-

Marine Propulsion Systems: Utilized in marine propulsion systems to transmit power from engines to propeller shafts while incorporating emergency braking features for maneuverability and safety.

Brake disc main size,mass,moment of inertia

Note:1.The mass and moment of inertia are the approximate values calculated according to theY-shaped shaft hole diameter of the largest shaft hole,and the brake wheel is not calculated.The brake wheel mass is shown in the table of"main size,mass and moment of inertia of the brake wheel".

2.Maximum shaft hole diameter of cone shaft to 220mm.

3.The values ofC,Gand C2 of different brake wheel diameters are the values in the table plus K/2,and the K values are shown in the table of"main size,mass and moment of inertla of brake discn

4.N=5-K/2;The values ofS and Kareshownin Table4-21.The value Nin the table is thecalculated value when the diameter ofthe brake disc is the largest.

Future Outlook: The integration of drum gear couplings with brake discs represents a significant advancement in power transmission technology, offering enhanced safety and operational efficiency across various industrial sectors. As industries continue to prioritize safety and reliability, the demand for innovative coupling solutions capable of combining power transmission and braking functionalities is expected to grow. Further research and development efforts may focus on optimizing the design, materials, and performance characteristics of drum gear couplings with brake discs to meet evolving industrial requirements and regulatory standards.