Copyright © 2025 Chuangming Coupling (Jiangsu) Co.,Ltd.

GCC Vertical installation drum gear coupling(Q/YG 13014X-2018)

Introduction: The GCC Vertical Installation Drum Gear Coupling represents a cutting-edge solution in the realm of mechanical power transmission, specifically designed for vertical applications. Renowned for its robust design, precision engineering, and adaptability, this coupling plays a pivotal role in ensuring reliable torque transfer in vertical shaft arrangements.

Key Features:

-

1.Vertical Installation Design: The GCC coupling is explicitly engineered for vertical installations, where the transmission of power occurs between vertically aligned shafts. Its unique design addresses the challenges associated with such configurations, providing optimal performance in a vertical orientation.

-

2.Drum Gear Configuration: The coupling features a drum gear configuration, enhancing its ability to handle misalignments and shock loads effectively. The drum gear design ensures uniform torque distribution, reducing stress on connected equipment and promoting smoother operation.

-

3.High-Torque Capacity: Built to withstand heavy loads, the GCC Vertical Installation Drum Gear Coupling boasts a high-torque capacity. This makes it suitable for applications where significant power transmission is required, such as vertical pumps, turbines, and other equipment.

-

4.Durable Materials: Crafted from durable and wear-resistant materials, the coupling ensures longevity even in demanding environments. Its construction materials are chosen to resist corrosion, minimize wear, and maintain performance integrity over extended periods.

-

5.Alignment Flexibility: The GCC coupling offers flexibility in accommodating angular, parallel, and axial misalignments, ensuring optimal shaft alignment. This adaptability is crucial in applications where precise alignment might be challenging due to varying operating conditions.

Applications: The GCC Vertical Installation Drum Gear Coupling finds its niche in industries with vertical power transmission requirements. Common applications include vertical pumps, compressors, generators, and other machinery where efficient torque transfer in a vertical orientation is essential.

Installation and Maintenance:

Designed with user convenience in mind, the GCC coupling facilitates straightforward installation and maintenance. Its user-friendly features streamline the setup process, and periodic maintenance requirements are minimal, contributing to overall operational efficiency.

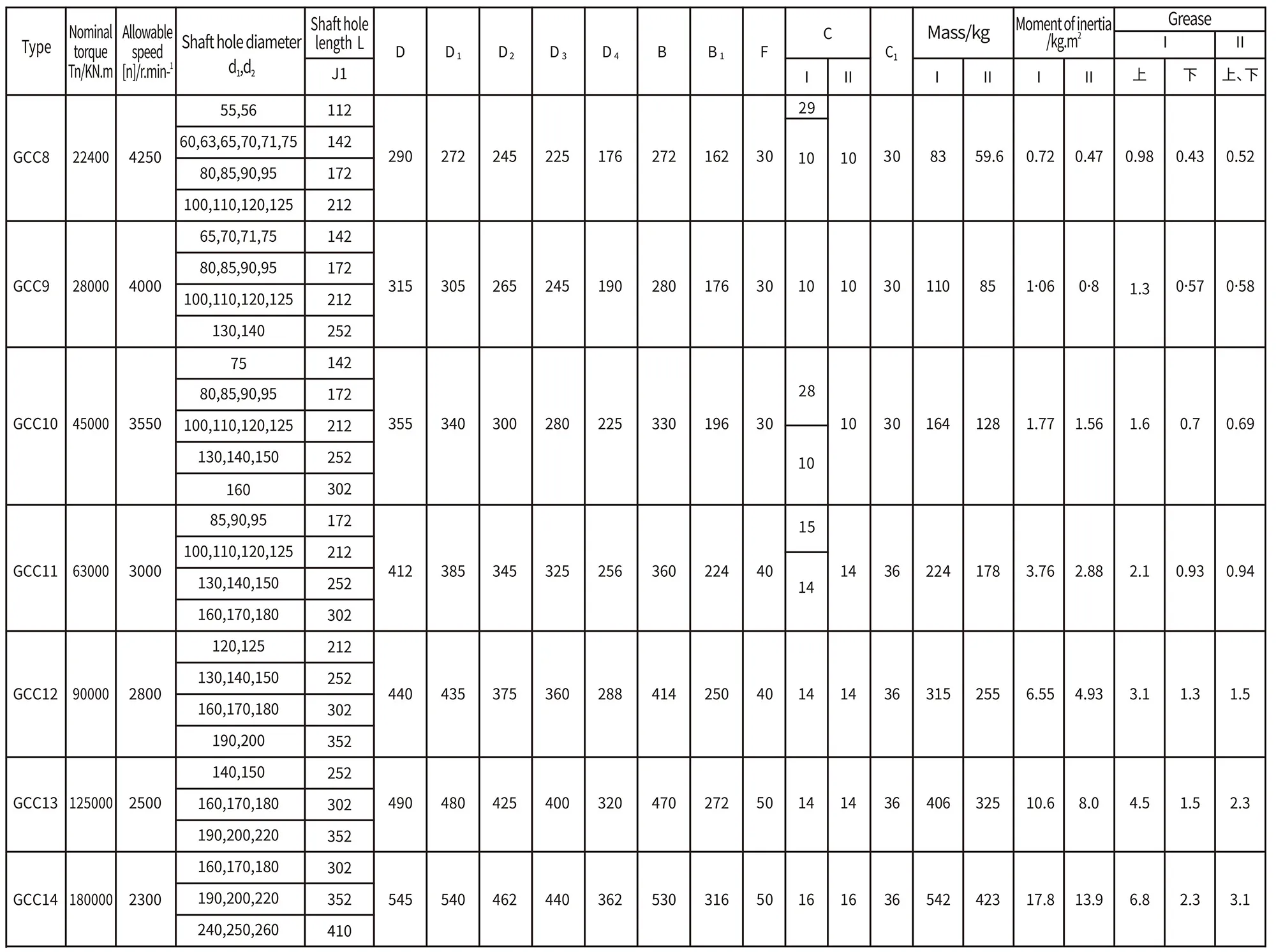

Basic parameters and main dimensions of GCC vertical mounting drum gear coupling

Conclusion: In the realm of vertical power transmission, the GCC Vertical Installation Drum Gear Coupling stands as a reliable and durable solution. Its purpose-built design, high-torque capacity, and adaptability make it a preferred choice for industries seeking efficiency and longevity in vertical shaft configurations.

Note:The mass and moment ofinertia are approximate values calculated by the Y-shaped shaft hole with the largest shaft hole diameter.

Introduction: The GCC Vertical Installation Drum Gear Coupling represents a cutting-edge solution in the realm of mechanical power transmission, specifically designed for vertical applications. Renowned for its robust design, precision engineering, and adaptability, this coupling plays a pivotal role in ensuring reliable torque transfer in vertical shaft arrangements.

Key Features:

-

1.Vertical Installation Design: The GCC coupling is explicitly engineered for vertical installations, where the transmission of power occurs between vertically aligned shafts. Its unique design addresses the challenges associated with such configurations, providing optimal performance in a vertical orientation.

-

2.Drum Gear Configuration: The coupling features a drum gear configuration, enhancing its ability to handle misalignments and shock loads effectively. The drum gear design ensures uniform torque distribution, reducing stress on connected equipment and promoting smoother operation.

-

3.High-Torque Capacity: Built to withstand heavy loads, the GCC Vertical Installation Drum Gear Coupling boasts a high-torque capacity. This makes it suitable for applications where significant power transmission is required, such as vertical pumps, turbines, and other equipment.

-

4.Durable Materials: Crafted from durable and wear-resistant materials, the coupling ensures longevity even in demanding environments. Its construction materials are chosen to resist corrosion, minimize wear, and maintain performance integrity over extended periods.

-

5.Alignment Flexibility: The GCC coupling offers flexibility in accommodating angular, parallel, and axial misalignments, ensuring optimal shaft alignment. This adaptability is crucial in applications where precise alignment might be challenging due to varying operating conditions.

Applications: The GCC Vertical Installation Drum Gear Coupling finds its niche in industries with vertical power transmission requirements. Common applications include vertical pumps, compressors, generators, and other machinery where efficient torque transfer in a vertical orientation is essential.

Installation and Maintenance:

Designed with user convenience in mind, the GCC coupling facilitates straightforward installation and maintenance. Its user-friendly features streamline the setup process, and periodic maintenance requirements are minimal, contributing to overall operational efficiency.

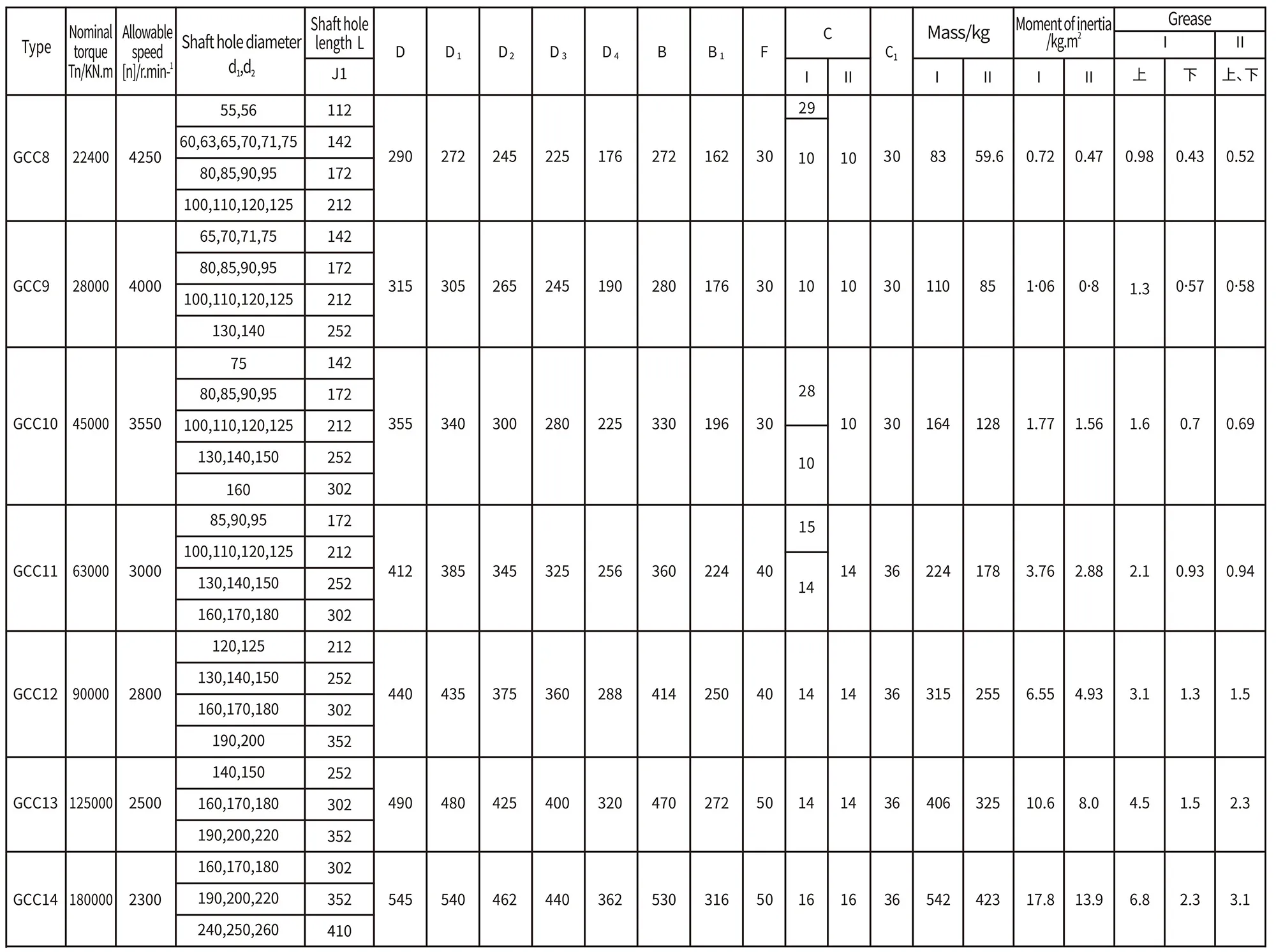

Basic parameters and main dimensions of GCC vertical mounting drum gear coupling

Conclusion: In the realm of vertical power transmission, the GCC Vertical Installation Drum Gear Coupling stands as a reliable and durable solution. Its purpose-built design, high-torque capacity, and adaptability make it a preferred choice for industries seeking efficiency and longevity in vertical shaft configurations.

Note:The mass and moment ofinertia are approximate values calculated by the Y-shaped shaft hole with the largest shaft hole diameter.