Copyright © 2025 Chuangming Coupling (Jiangsu) Co.,Ltd.

Coupling installation deviation and unbalance amount

2025-07-25

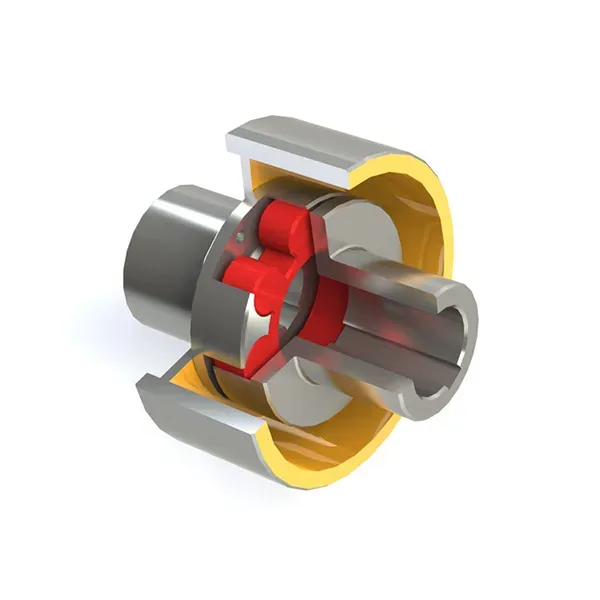

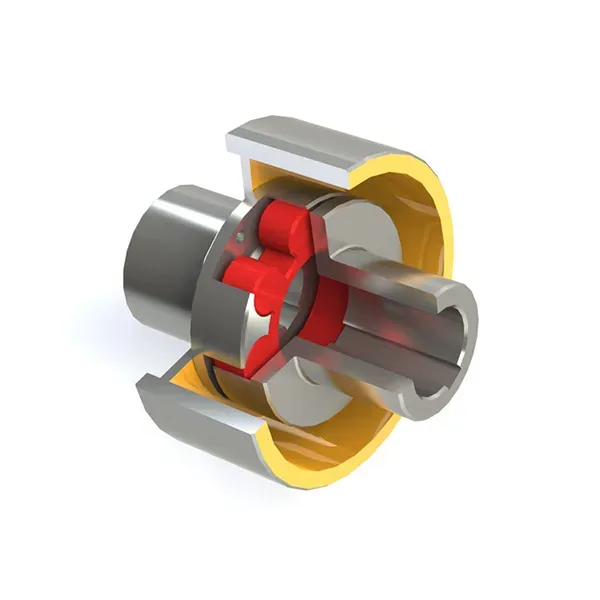

When installing this equipment, it is also necessary to pay attention to controlling the deviation. Although it allows a large error value, the installation process should still be within the specified range. The internal components of the equipment are few, so it is light in weight and small in size, making it convenient for storage and carrying. Even if there is a large error during installation, it will not affect the performance of the equipment. Use dry oil gun to inject grease until there is excess grease overflowing from the hole. Under normal load, the distance between the contact points of the teeth does not change with the deformation, and the relative rotation angle of the coupling and the transmitted torque have a linear relationship.

Before installing the diaphragm coupling, it is necessary to check whether the two shafts of the prime mover and the working machine are concentric, and whether there is any packaging paper or damage on the surface of the two shafts. Also, check if there is any debris in the inner holes of the two half couplings and whether the inner hole edges are damaged. If so, clean the shafts and the half couplings thoroughly and use a fine file to smooth out any damage. The diaphragm coupling is composed of several groups of diaphragms which are alternately connected to the two half couplings by bolts. Each group of diaphragms is made up of several pieces stacked together. Diaphragms are available in both connecting rod type and various integral shapes. Whether the unbalance of the coupling can meet the requirements of any rotating system depends on the performance of the specific machines being coupled.

The coupling has good vibration damping performance and a long service life. It can handle large load variations and has a decent transmission rate. It allows for significant installation deviations. The coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the shaft sleeves with pins and is generally not likely to loosen or cause rebound between the diaphragm and the shaft sleeves. There is one or two rigid elements in the middle, and they are connected to the shaft sleeves on both sides. It can meet the standards of different torque, speed and working conditions for standard couplings in various structural types and specifications. The way the coupling transmits torque is similar. When relative displacement load is generated, it is easy to bend.

When installing this equipment, it is also necessary to pay attention to controlling the deviation. Although it allows a large error value, the installation process should still be within the specified range. The internal components of the equipment are few, so it is light in weight and small in size, making it convenient for storage and carrying. Even if there is a large error during installation, it will not affect the performance of the equipment. Use dry oil gun to inject grease until there is excess grease overflowing from the hole. Under normal load, the distance between the contact points of the teeth does not change with the deformation, and the relative rotation angle of the coupling and the transmitted torque have a linear relationship.

Before installing the diaphragm coupling, it is necessary to check whether the two shafts of the prime mover and the working machine are concentric, and whether there is any packaging paper or damage on the surface of the two shafts. Also, check if there is any debris in the inner holes of the two half couplings and whether the inner hole edges are damaged. If so, clean the shafts and the half couplings thoroughly and use a fine file to smooth out any damage. The diaphragm coupling is composed of several groups of diaphragms which are alternately connected to the two half couplings by bolts. Each group of diaphragms is made up of several pieces stacked together. Diaphragms are available in both connecting rod type and various integral shapes. Whether the unbalance of the coupling can meet the requirements of any rotating system depends on the performance of the specific machines being coupled.

The coupling has good vibration damping performance and a long service life. It can handle large load variations and has a decent transmission rate. It allows for significant installation deviations. The coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the shaft sleeves with pins and is generally not likely to loosen or cause rebound between the diaphragm and the shaft sleeves. There is one or two rigid elements in the middle, and they are connected to the shaft sleeves on both sides. It can meet the standards of different torque, speed and working conditions for standard couplings in various structural types and specifications. The way the coupling transmits torque is similar. When relative displacement load is generated, it is easy to bend.